Where can DoE fit in process development?

Are you using DoE to its full potential?

A common misconception with experimental design in chemistry is that its use comes once a process had been planned and tested, just before commercialisation. In fact, DoE is arguably more useful at the start of a process for efficiently screening a large number of variables to understand the reaction.

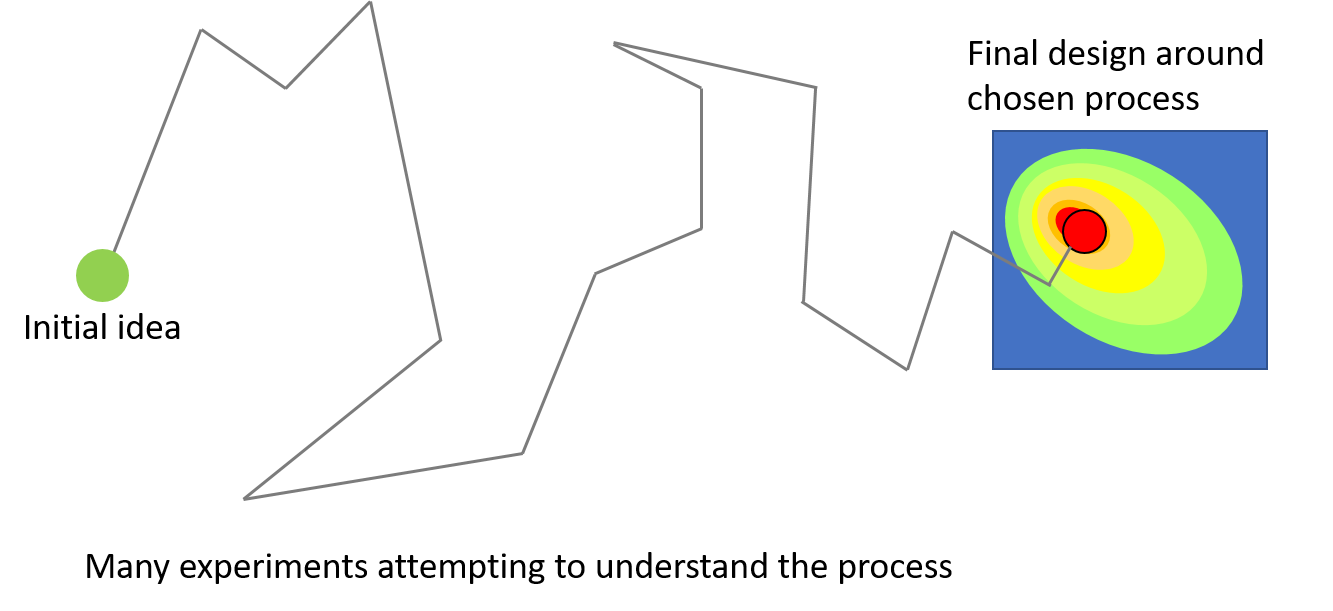

The traditional approach for chemical development is to start from an idea consisting of several reactions in a route and find a process for each step, understanding more about it as the months progress and the work builds up. Once the route has been proven and optimised, a design may be carried out to ensure all the critical process parameters are assigned and controlled.

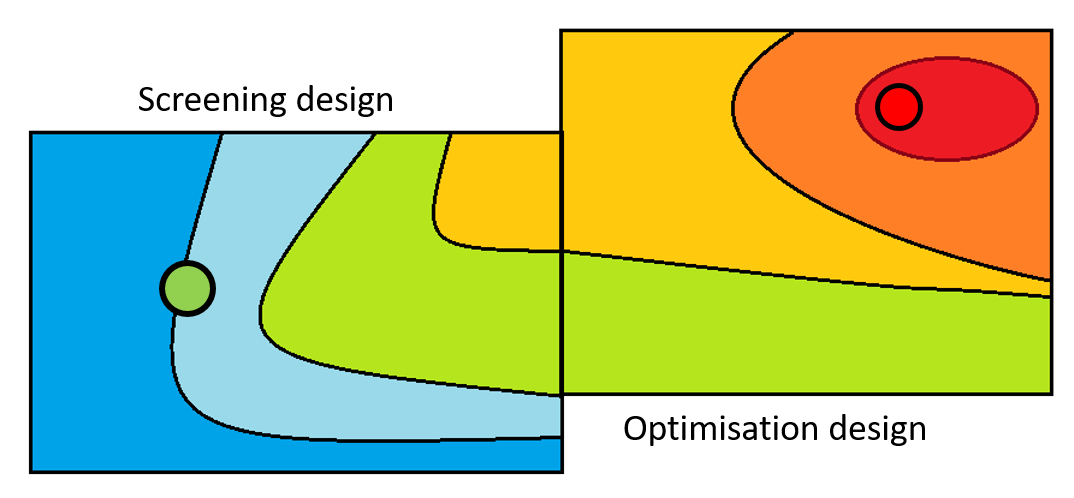

A better way of combining experimental design with efficient process development is to do the design at the start of the process to understand the factors that are affecting the chemistry of the investigated route. This will allow chemists to see early on if the route they have chosen is chemically robust, or, if problems arise they can be corrected, possibly by finding an alternative process.

If a problem is highlighted when a design is performed in the final stages following a lot of time and effort, the problem tends to be ‘patched up’ when it may be preferable to use a different route entirely. If a potential problem is flagged before months or indeed years of work have passed, it could be easier and safer to change the route.

Following the initial screening design, a follow up optimisation design will provide additional knowledge about the reaction. A complete view of the process and reaction space allows for careful choosing of the best and most robust process conditions to ensure quality. Additionally, DoE will give an understanding of the risks in the process and how to mitigate these. All sources of variability will have been identified, considered, and controlled early on in the process and can be managed by choosing the correct conditions.

To get the most from your screening design, careful factor selection is necessary. A foundation of knowledge about the reaction will help in choosing factors to investigate and this may come from previous work or literature precedence. Sighting experiments can help, however, there is a balance to strike between large numbers of sighting experiments and not having enough information to identify the correct factors, leading to a larger design to accommodate too many insignificant factors. A future post will cover factor selection in more detail.

While robustness designs are extremely useful in proving that the operating space is without risk for the process and a response surface design gives a lot of detailed information about few factors around their set points, next time you are at the early stages of development consider a screening design to gain greater understanding of your chemistry sooner. In our experience, you will get much more information, design a much better process and do less work overall!