What design to use and when

DoE is a structured approach for determining the influencing factors in a reaction and the relationships between them. There are different designs in DoE which serve different purposes and choosing the correct design type to suit the purpose is critical for exploiting the benefits of DoE i.e. increased efficiency and reduced development time. With four different design types and further options within these it can be difficult to know which design is best. The four main design types are:

Screening designs: used to determine which factors are important for the reaction under scrutiny. Typically, a larger number of factors will be screened in a lower resolution design.

Optimisation designs: these direct the investigation onto the chemical space of interest, i.e. the factors which were highlighted as being important during the screening design are probed in the correct range.

Response surface designs: used for detailed reaction or process modelling. Should be used when the model includes a squared term.

Robustness designs: act to confirm understanding across the entire operating range. This is carried out at the end of process development, typically before filing for process approval.

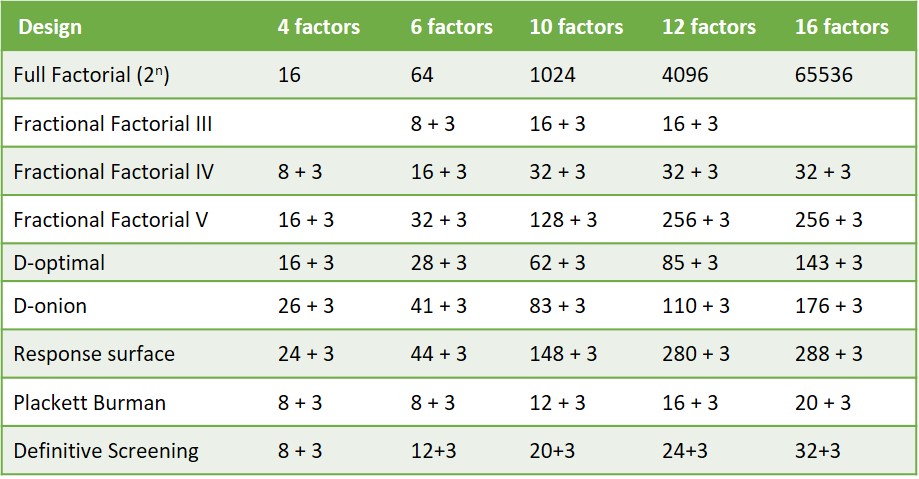

Screening and robustness designs look at the factors at 2 levels (with a mid-point), whereas response surface designs will look at multiple levels. This means that more experiments are required for a response surface design. The number of experiments to be performed varies greatly across designs and will often be a deciding factor in choosing the design type. The table below illustrates the number of experiments to be performed for a selection of design types with varying numbers of factors.

If you are using DoE for screening a reaction process and have 10 factors to look at, a fractional factorial resolution IV design will give you enough information to determine the important parameters in 35 experiments whereas a response surface design would need 151. Of course you will gain more information from the response surface design, as is to be expected, but an alternative is to do a follow-on screening design just looking at the factors which were identified as important in the first round. This will reduce the overall number of experiments and time.

While most reactions will feature interactions, squared terms are less common. If, after a screening or optimisation design, your model does not include a squared term we would recommend performing a resolution V design for further information about the system rather than a response surface. This is because it will require fewer experiments overall.

There are too many pros and cons for each design to detail in this ‘simplified DoE’ post. Our aim is to steer you to take advantage of screening designs with lower numbers of required experiments and to not use response surface designs when they are not needed. If you need more help with selecting designs please get in touch.